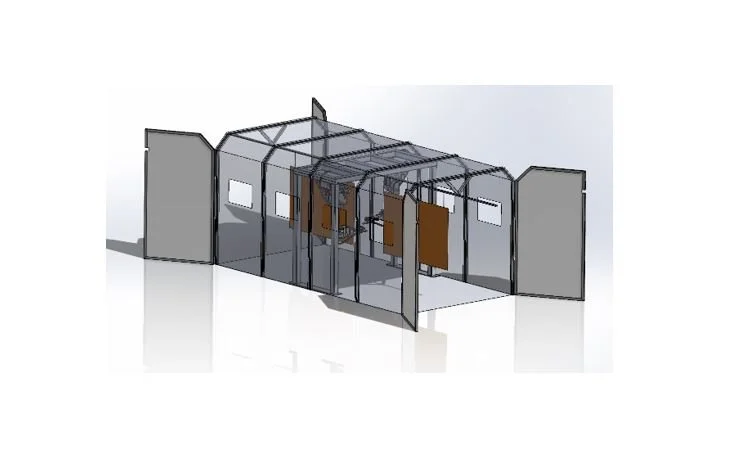

Custom Automation Equipment

Bekkala Engineering builds custom automation systems and assembly equipment to improve our customers’ manufacturing processes. We work closely with you to design and build automated systems that meet your application needs. Looking to improve output? Looking to reduce manufacturing costs? These are benefits to using automation in your facilities. We update and replace old equipment as well as build new automation systems to meet the demands of today’s manufacturing. As an automation system integrator, we will get your new equipment integrated seamlessly into your existing workflow.

Custom Automation Systems For Multiple Industries

We design automated systems and equipment for numerous processes including straightening, milling, and assembly that are unique to each industry.

These systems fit seamlessly into your existing manufacturing workflow, helping to meet your goals. We understand the process to determine your ROI when investing in custom automation equipment. With automated assembly equipment, companies can:

remove production bottlenecks and increase productivity,

reduce manual parts handling and improve standardization,

improve quality control and product accuracy,

and increase throughput and cost savings.

We have completed projects and improved the bottom line for lawn mower blade manufacturing, automotive and construction equipment, medical automation, oil and gas, and more.

Our Process

We will work closely with you to build a custom automated machine or system that fits your process. From concept and brainstorming to installation and system integration, we are with you every step of the way. We have a straightforward process with open communication throughout the project.

Our project deliverables include part, assembly, and electrical drawings, manuals, parts lists, equipment, tooling and fixtures.

-

Work with sale and engineers, concept and brainstorming, design a solution, and generate a proposal based on budget, timeline, and support program needed.

-

Develop the design concept with initial testing, fabricate and assemble, and integration and controls.

-

Debug and testing, internal test runs, Factory Acceptance Test (FAT), and shipping.

-

Install new systems, integrate systems into your workflow, and perform Site Acceptance Test (SAT).

-

Implement support program.

Custom Automation Projects